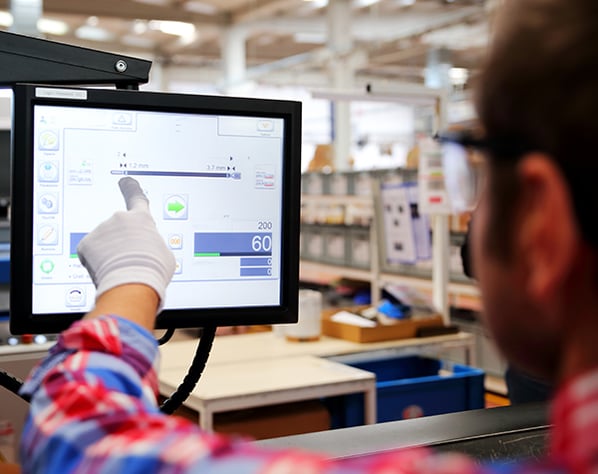

The world has a lot of good MES and OEE systems, but not all of them are right for your business

It doesn’t matter if your company is investing in MES, MOM or an OEE solution for the first time, or exploring options to modernize an existing system. Look to the experts in ISA-95 levels 1-4 systems and applications to help you understand which options will work best for your specific operations. Our systems experts and manufacturing performance consultants won’t just give advice then disappear. We partner with you every step of the way, making sure you get the right system, implemented the right way, so it works the way it’s supposed to, and delivers the value you expect. Work with the systems partner that can help you wherever you are in the initiative:

- Align with business objectives

- Solution selection

- System design

- Implementation and integration

- Change management and training

- Ongoing maintenance and support

Shop floor systems and improvement initiatives that get results and deliver long-term business value

Getting the right solution up and running the right way is just one step in your transformation journey. Technology alone can’t boost performance, yet a continuous improvement program without the right technology support usually isn’t enough.

A manufacturing company that aligns people, processes, and technology can make continuous improvement the foundation for world-class manufacturing. We can help your company achieve its business goals with continuous improvement and a consistent focus on throughput, capacity, quality, cost, and delivery.

Do more and get more value from your existing MES, MOM, or OEE system

Every shop floor system should drive incremental value over time. Are there hidden improvements you can unlock by asking questions like:

- Are we using all the features to our best advantage?

- Do our people have creative ideas to maximize the information already available to them?

- Can we integrate our MES / OEE with existing applications for even more visibility?

- Should we connect more machines, other equipment?

- Can our existing system provide data to fuel new applications in other areas?

Even if your MES or OEE project stalled, or your people aren’t using the system as much as you’d like, you don’t necessarily have to pull out the system and replace it with something new. A value assessment can reveal ways to restart your initiative and start making gains with what you already have in place.

Connect CNC machines to do more with your MES or OEE system

Data from CNC machines is sometimes a gap when it comes to analyzing operations performance or even effective production scheduling. Capturing CNC machine data unlocks valuable insights to optimize operations like never before. Unlock your CNC machine data now to maximize efficiency.

Integration creates a more robust and responsive business operation

Manufacturing companies eager for digital transformation have a high appetite for MES or OEE integration with their business system, supply chain platform, production scheduling application, and other systems. Even small and mid-size manufacturers can quickly and easily integrate shop floor applications and data with other systems, to compound the value they can achieve with solutions already in place.

We help your company feed production data to operational and business systems for:

- Accurate shop floor data to fuel other systems

- Automated reporting

- Optimized production schedule

- Optimal preventive maintenance for less downtime and fewer changeovers

- Improved supply chain planning

- Better traceability and compliance