Digital Transformation Strategy and Execution That Gets the Results You Expect

Every manufacturing company needs a digital transformation partner with the depth and breadth of expertise to map out and deliver the right solutions, at the right time, in the right way.

Trusted by these companies

Digital transformation should help you do better, not take up all your time and resources

The ultimate definition of transformation success is a more profitable business through manufacturing excellence and an agile, responsive supply chain. It’s not enough to “want” transformation success, but it’s complicated.

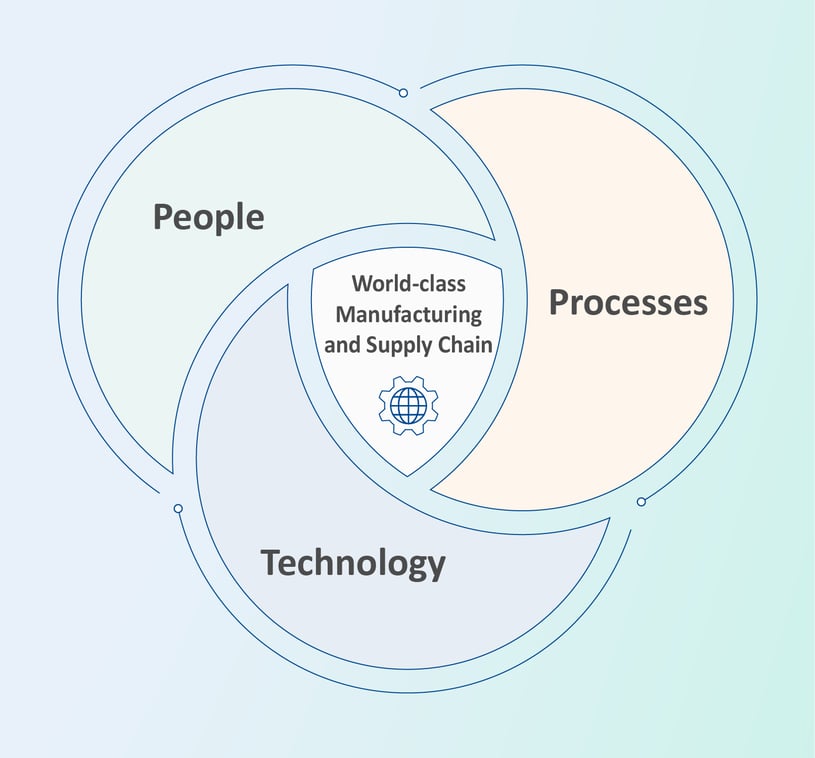

We help you plan and execute successful digital transformation projects. We make sure you align people-processes-technology, so your project goes as planned and delivers the business results you expect.

Which digital transformation project is the right one?

A lot of manufacturing companies aren’t sure which projects to tackle first. Or if budget is limited, you want to be sure the company picks the right project to maximize available funding.

A value assessment examines and compares your current situation against desired outcomes. Our transformation experts make recommendations about investment priorities, timing, cost, and anticipated performance impact.

We assess the organization dimensionally, which often includes:

- Production network and individual plants

- Production processes and shop floor business processes

- Workforce and culture

- Business objectives

- Perceived waste and actual performance metrics

- Existing technologies and integrations

- Data availability and gaps

Every value assessment helps your company understand:

- General project and technology readiness

- Data gaps and needs

- Technology and operational improvement roadmap

- Value estimates by category expressed in short-term and long-term estimates

- Recommendations for order of priorities

Aligning people-processes-technology is first step for transformation success

Most companies have strategic goals in mind when they launch an initiative, but often they skip directly to solution implementation or system integration.

To help your digital transformation effort succeed, we help your company examine the current environment and processes, understand the people and culture, and analyze the potential value of each transformation element. Every successful project includes the right elements for:

- Clear, measurable performance impact

- Engaged, supportive shop floor employees and supervisors

- Compelling software pilots that meet time and value targets

- Predictable program and software adoption

- Successful program or software implementations that meet stated goals

- Business performance reflects shop floor metrics gains

Accelerate digital transformation for the greatest impact on your business

Gather the right people from each discipline

No one knows your business better than the people in it. Manufacturing companies that put people first and encourage engagement are more successful with transformation initiatives. Every project we work on includes your people and teams who will touch the system and those who are affected by it.

Use the right people at the right time

It takes a lot of different skills to get results with digital transformation, which is why we use a lot of different experts for every project: delivery managers, consultants, industrial engineers, data and applications architects, operations IT experts, improvement experts, and many others.

Apply a proven methodology

We run projects the same way every time, using a proven deployment methodology. Part of that process is understanding how your business runs today, how it needs to change to make the most of digitalization investments, and aligning people-processes-technology to get the desired results. We invest heavily in our people and technology so your transformation project gets fast results.

Manage change the right way

Managing change isn’t easy, especially when people have done things the same way for a long time. We help you eliminate skills gaps, identify tactical organizational changes, and implement best practices that improve adoption, accelerate time-to-value, and create sustainable results.

Proven methodology for an agile, integrative approach to project management

Deploying and integrating your new system requires so much more than just “setting up the software” and training your people. When you’re focused on implementing new digital capabilities or integrating with other systems, you want a transformation partner with a proven project management methodology, and engineers and consultants who consistently apply it. Our approach to project management allows us to address the cultural shift and business process changes required to get the business results your company expects. As a result, we help you fully align people, processes, and technology to create an environment prepared to deliver world-class manufacturing.

We apply an integrative approach to project management and we assemble a delivery team with diverse expertise for every project:

- Experienced delivery managers (project managers)

- Manufacturing domain experts (industry, discipline)

- Change management experts

- Technology-specific engineers and consultants

- Data specialists, architecture specialists

- Documentation and training teams

- Managed services

Helpful Resources

Get the value you expect from transformation, quickly and sustainably.

Digital transformation is our business. We are experts at deploying and integrating supply chain solutions and smart manufacturing systems – on time and within budget.

-

Digital transformation experts

-

Manufacturing and industry experts

-

Proven methodology

-

Change management